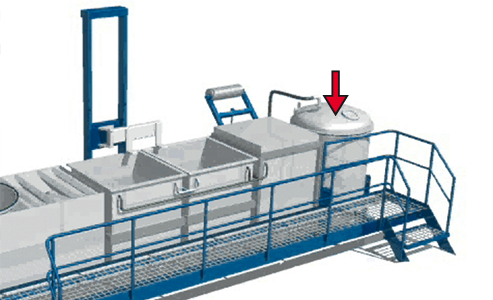

Maldaner Impregnation System

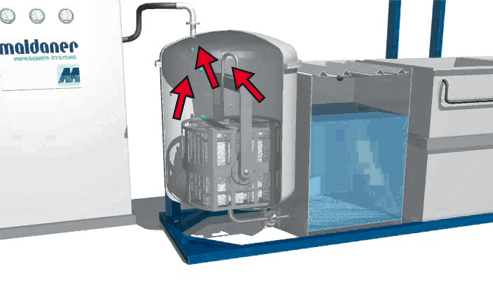

- Dry Vacuum

- Wet Vacuum

- Atmospheric Pressure

- Washing

- Curing

- Drying

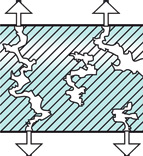

The prerequisite for best impregnation results is that the work pieces are free of grease and the internal porosity is clean and completely dry. By applying a vacuum of less than 10 mbar the air trapped in the porosity is evacuated.

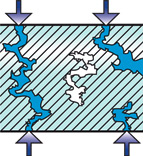

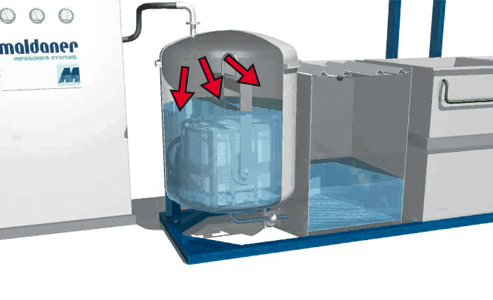

Impregnation sealant can penetrate into the porosity due to the vacuum removing all of the air.

After the vacuum has been released, the impregnation sealant is forced into the porosity by atmospheric pressure and thus penetrates even the finest porosity.

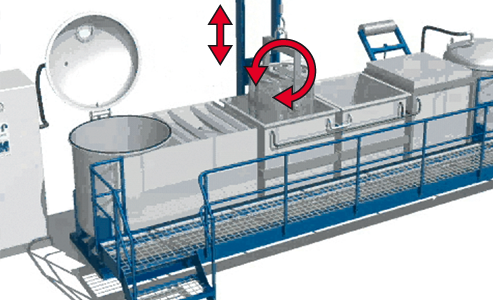

In a water bath the components surface is washed so no surface film remains. No additional washing is necessary afterwards.

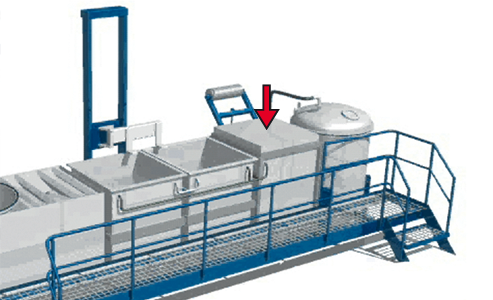

Curing of the sealant takes place in the polymerisation bath at 90 °C. Rapid initial curing at the surface prevents bleeding out of the sealant from the porosity.

Vacuum drying of the hot components ensures dry work pieces and prevents corrosion by residual moisture.

If the video isn't played back, you can use the direct link to the video file.